Cutting Torch Settings Chart

Cutting Torch Settings Chart - Web a cutting torch guide that covers equipment, settings, gas, safety, how to light the torch, and more. Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. While a cutting torch is a pretty. Web match your torch type, your cutting fuel, and your material thickness to begin reviewing which tip size is appropriate for your cutting setup. Web there's lots of info in that chart but i still have two questions: Web cutting tip series gpn, hpn. Regulator pressures are for 50 ft (13 m) or less of 3/8 in. By understanding the basics, selecting the right tip, setting proper gas pressures, and following the correct cutting techniques, you. Web follow these steps carefully: Tighten them, but not too forcefully, as you’ll need to remove. Determine the thicknesses of steel to be cut. Web match your torch type, your cutting fuel, and your material thickness to begin reviewing which tip size is appropriate for your cutting setup. A cutting torch is found in all types of shops and on construction sites. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. That means having a thorough understanding of how exactly a blow torch, or cutting torch, works. Maximum acetylene pressure is 15 psi and it should not go any higher! How to use a cutting torch! By understanding the basics, selecting the right tip, setting proper gas pressures, and following the correct cutting techniques, you. Web setting the correct working pressures. Web mastering the oxy acetylene cutting torch settings is essential for achieving clean and efficient cuts. Ensure that the connections are tight and secure. Web setting the correct working pressures. Web follow these steps carefully: Increase regulator pressures if longer hose or smaller i.d. 2) i didn't find settings for rosebud tips. Settings should be used for a rodebud with eight (8).043 ø orifices (orifii?)? Web there's lots of info in that chart but i still have two questions: Maximum acetylene pressure is 15 psi and it should not go any higher! Web match your torch type, your cutting fuel, and your material thickness to begin reviewing which tip size is appropriate. Web an oxy acetylene torch is an affordable and versatile tool used by many people to heat, weld, solder, and cut metal. Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. Use the charts below as recommended settings to use on your regulators for your cutting torch tips. 2) i. Licable for three hose machine torch only. By understanding the basics, selecting the right tip, setting proper gas pressures, and following the correct cutting techniques, you. That means having a thorough understanding of how exactly a blow torch, or cutting torch, works. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger.. Look over the article for helpful tidbits of information, or glance at each tip chart for quick answers to the most common torch tip questions. ** for best results use st2600fc series torches and. Determine the manufacturer and model number of the cutting torches and/or cutting attachments being used. **for best results use st 1600c / st 1900c or st. For a metal thickness over 7’ use 164 styles. Ensure that the connections are tight and secure. Eat pressure is set by the cutting oxygen. How to use a cutting torch! Settings should be used for a rodebud with eight (8).043 ø orifices (orifii?)? Web here we will discuss the various types of cutting torch tips and the best sizes for each job. While a cutting torch is a pretty. Web cutting torch tip flow charts. How to use a cutting torch! Determine the manufacturer and model number of the cutting torches and/or cutting attachments being used. Determine the thicknesses of steel to be cut. Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. Regulator pressures are for 50 ft (13 m) or less of 3/8 in. Look over the article for helpful tidbits of information, or glance at each tip chart for quick answers to the. Web mastering cutting torch settings for perfect cuts every time. Web when using tip size 6 or above, you need to use 3/8 inches hose in order to get the best results in the shortest period of time. Web here we will discuss the various types of cutting torch tips and the best sizes for each job. That means having. Ensure that the connections are tight and secure. Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. It uses extreme heat to function, and setting it up properly is one of the most important steps in using it safely. When you’re trying to make use of a cutting torch for. Web setting the correct working pressures. Use the charts below as recommended settings to use on your regulators for your cutting torch tips. Web an oxy acetylene torch is an affordable and versatile tool used by many people to heat, weld, solder, and cut metal. Data compiled using mild steel as test material. Determine the thicknesses of steel to be cut. Settings should be used for a rodebud with eight (8).043 ø orifices (orifii?)? **for best results use st 1600c / st 1900c or st 2600fc series torches and 3/8 hose when using tip size 6 or larger. Look over the article for helpful tidbits of information, or glance at each tip chart for quick answers to the most common torch tip questions. Web mastering cutting torch settings for perfect cuts every time. Web follow these steps carefully: Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. That means having a thorough understanding of how exactly a blow torch, or cutting torch, works. Web match your torch type, your cutting fuel, and your material thickness to begin reviewing which tip size is appropriate for your cutting setup. 2) i didn't find settings for rosebud tips. Increase regulator pressures if longer hose or smaller i.d. When you’re trying to make use of a cutting torch for the first time, you need to make sure you have all your ducks in a row.Cutting Torch Settings Chart

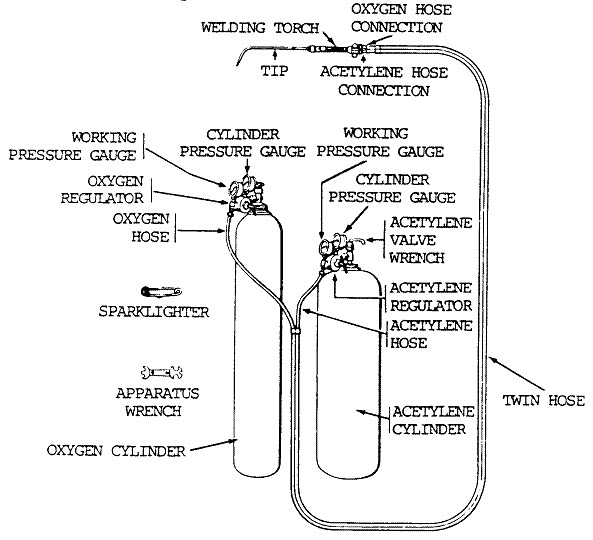

oxygen and acetylene pressure settings

Cutting Torch Settings Chart

Airco AFH / AFS Cut Chart American Torch Tip

Cutting Torch Settings Chart

Oxyacetylene Torch Settings Chart

Oxyacetylene Torch Settings Chart

Selecting the Right Cutting Tip RonSon’s Torch Repairs & Sales Ltd.

Cutting Torch Tip Flow Charts Baker's Gas & Welding Supplies, Inc.

Cutting Torch Guide

All Torches With Flashbacks Arrester Need More Pressure, 25% More Per Tip Increase.

Connect The Oxygen And Acetylene Hoses To Their Respective Gas Sources And The Torch Handle.

Make Use Of Correct Welding & Cutting Technique.

While A Cutting Torch Is A Pretty.

Related Post: