X And R Chart

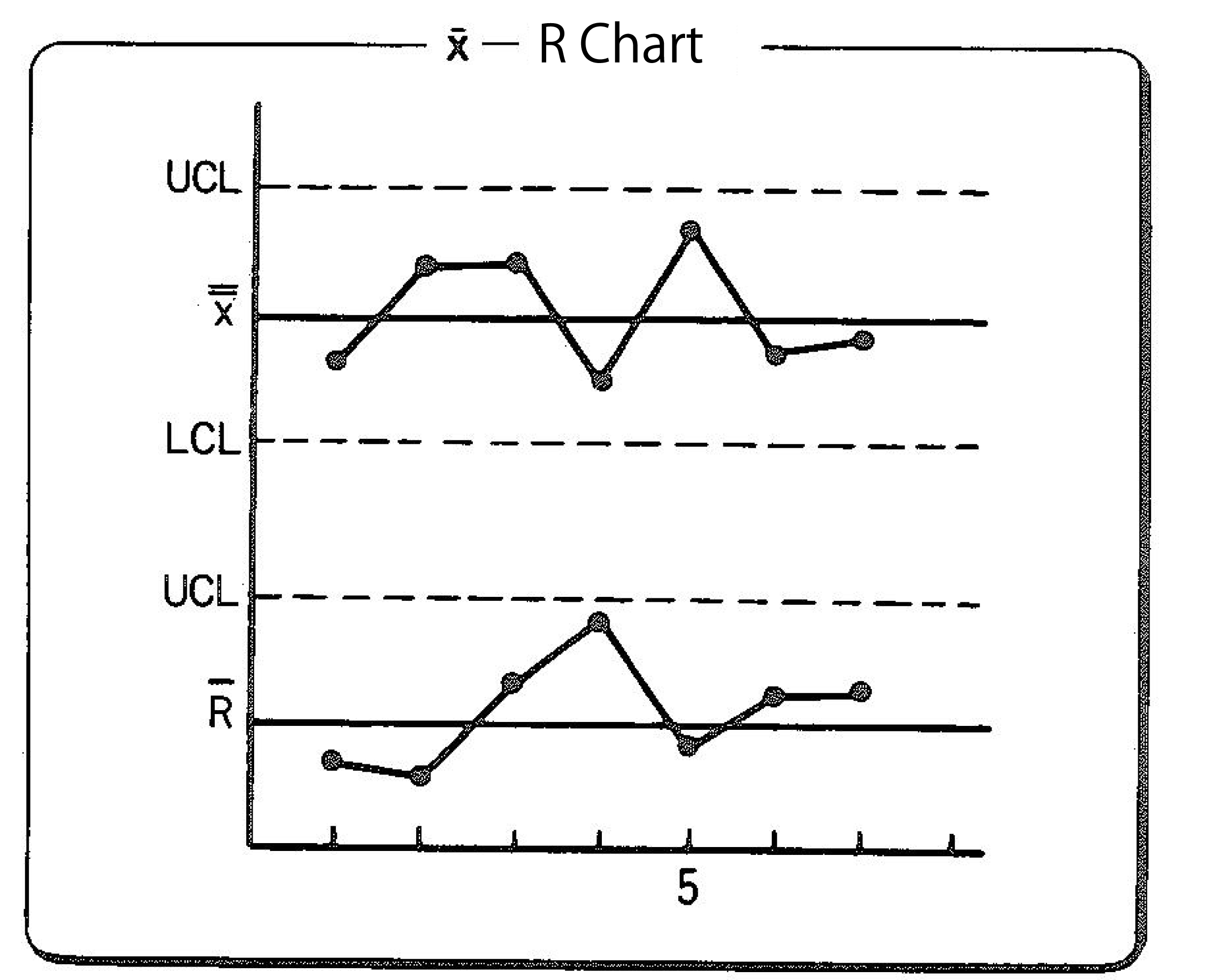

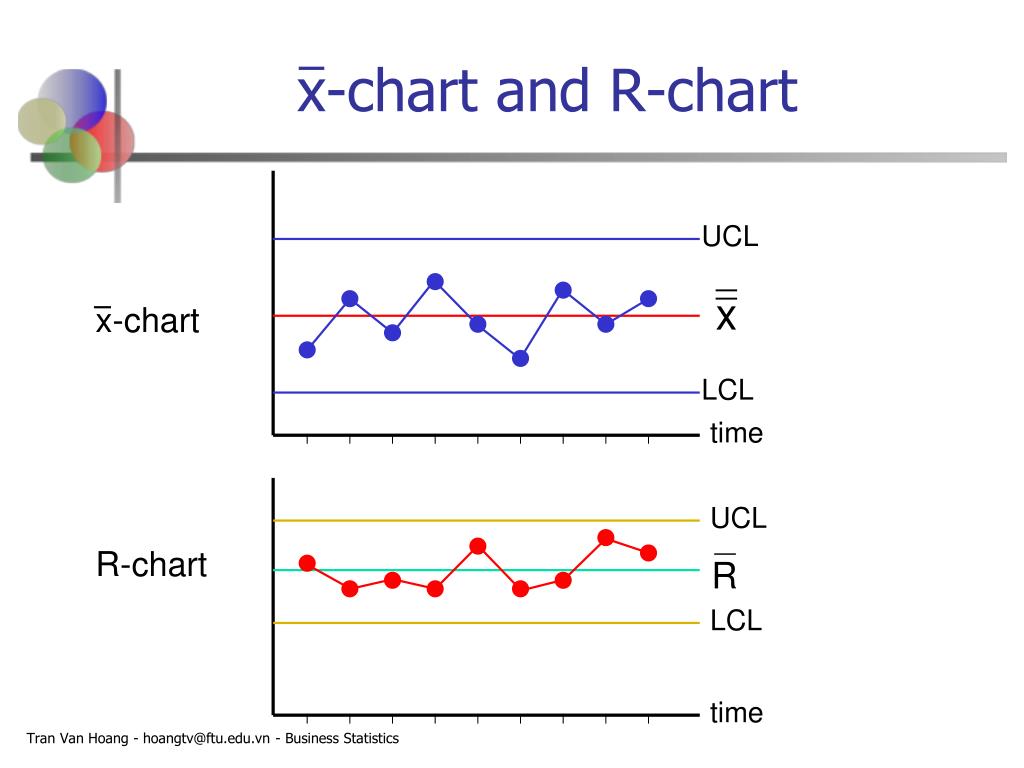

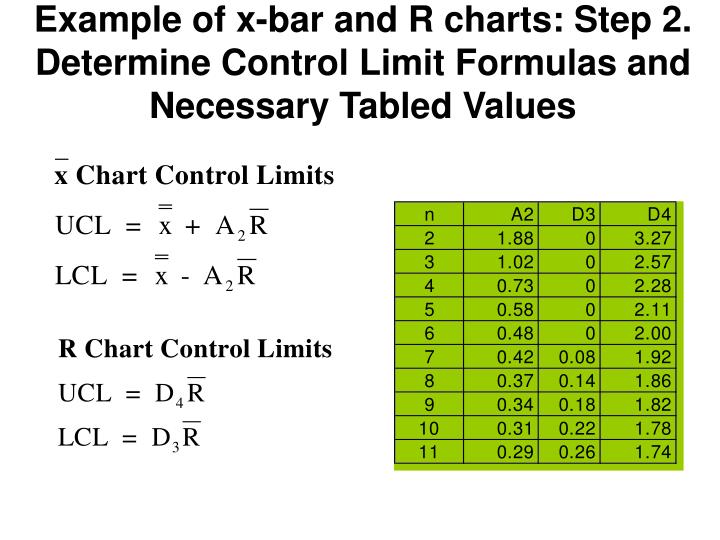

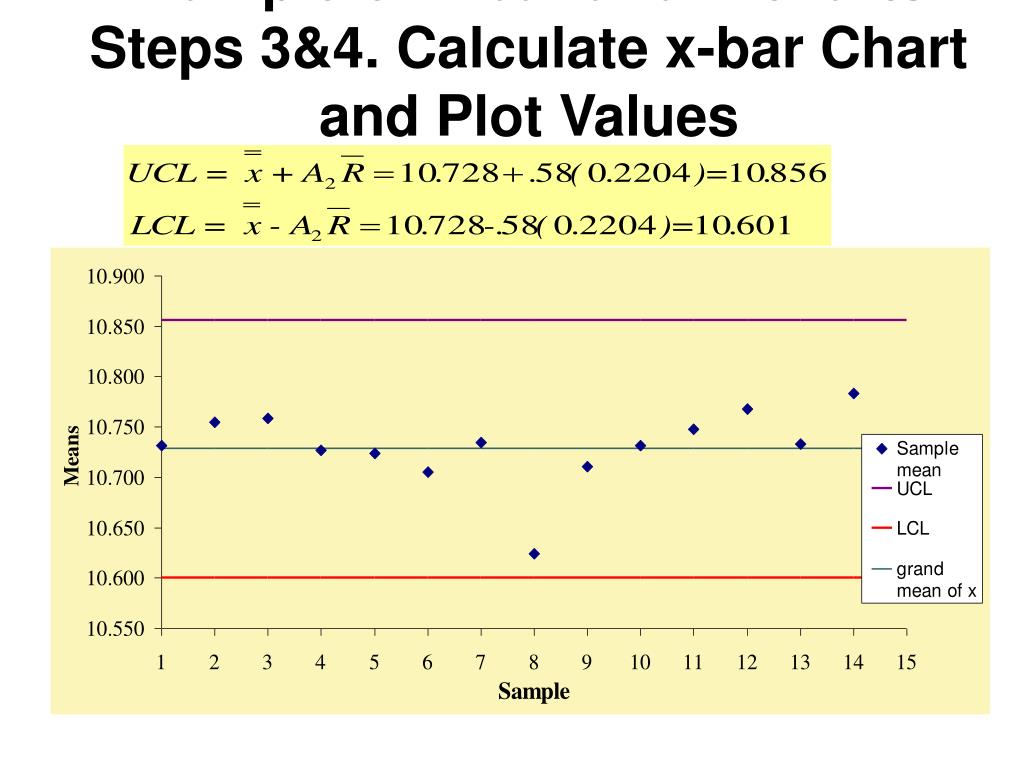

X And R Chart - X bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a. It plots the mean (x bar) and range (r) of each subgroup of samples. The control limits on both chats are used to monitor the mean and variation of the process going forward. Data points representing process outcomes. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Control charts typically contain the following elements: Control limits depict the range of normal process variability. Web in statistical process control (spc), the ¯ and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously, when samples are collected at regular intervals from a business or industrial process. Web the x bar & r chart is used for variable data that results in a measured value along a continuous scale (e.g. Web what are x bar r control charts? Web the x bar & r chart is used for variable data that results in a measured value along a continuous scale (e.g. Control limits depict the range of normal process variability. It plots the mean (x bar) and range (r) of each subgroup of samples. Web what are x bar r control charts? The control limits on both chats are used to monitor the mean and variation of the process going forward. Data points representing process outcomes. Control charts typically contain the following elements: X bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Web in statistical process control (spc), the ¯ and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously, when samples are collected at regular intervals from a business or industrial process. Control charts typically contain the following elements: Data points representing process outcomes. Web in statistical process control (spc), the ¯ and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously, when samples are collected at regular intervals from a business or industrial process. Web. Control charts typically contain the following elements: Web the x bar & r chart is used for variable data that results in a measured value along a continuous scale (e.g. Data points representing process outcomes. It plots the mean (x bar) and range (r) of each subgroup of samples. Control limits depict the range of normal process variability. Web in statistical process control (spc), the ¯ and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously, when samples are collected at regular intervals from a business or industrial process. X bar r charts are the widely used control charts for variable data. Web what are x bar r control charts? Control limits depict the range of normal process variability. Control charts typically contain the following elements: X bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a. Web. Web in statistical process control (spc), the ¯ and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously, when samples are collected at regular intervals from a business or industrial process. They provide continuous data to determine how well a process functions and stays. Web the x bar & r chart is used for variable data that results in a measured value along a continuous scale (e.g. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. The control limits on both chats are used to monitor the mean and variation of the process going forward.. Control limits depict the range of normal process variability. Control charts typically contain the following elements: They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Web in statistical process control (spc), the ¯ and r chart is a type of scheme, popularly known as control chart, used to monitor the mean. Control charts typically contain the following elements: Web in statistical process control (spc), the ¯ and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously, when samples are collected at regular intervals from a business or industrial process. It plots the mean (x bar). Web the x bar & r chart is used for variable data that results in a measured value along a continuous scale (e.g. Web what are x bar r control charts? X bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer. X bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a. It plots the mean (x bar) and range (r) of each subgroup of samples. The control limits on both chats are used to monitor the. Control charts typically contain the following elements: Web the x bar & r chart is used for variable data that results in a measured value along a continuous scale (e.g. Data points representing process outcomes. Control limits depict the range of normal process variability. Web in statistical process control (spc), the ¯ and r chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of a normally distributed variables simultaneously, when samples are collected at regular intervals from a business or industrial process. The control limits on both chats are used to monitor the mean and variation of the process going forward. Web what are x bar r control charts? They provide continuous data to determine how well a process functions and stays within acceptable levels of variation.xR Chart Quality Control MRP glossary of Production scheduler Asprova

How To Create an XBar R Chart Six Sigma Daily

X Bar And R Chart

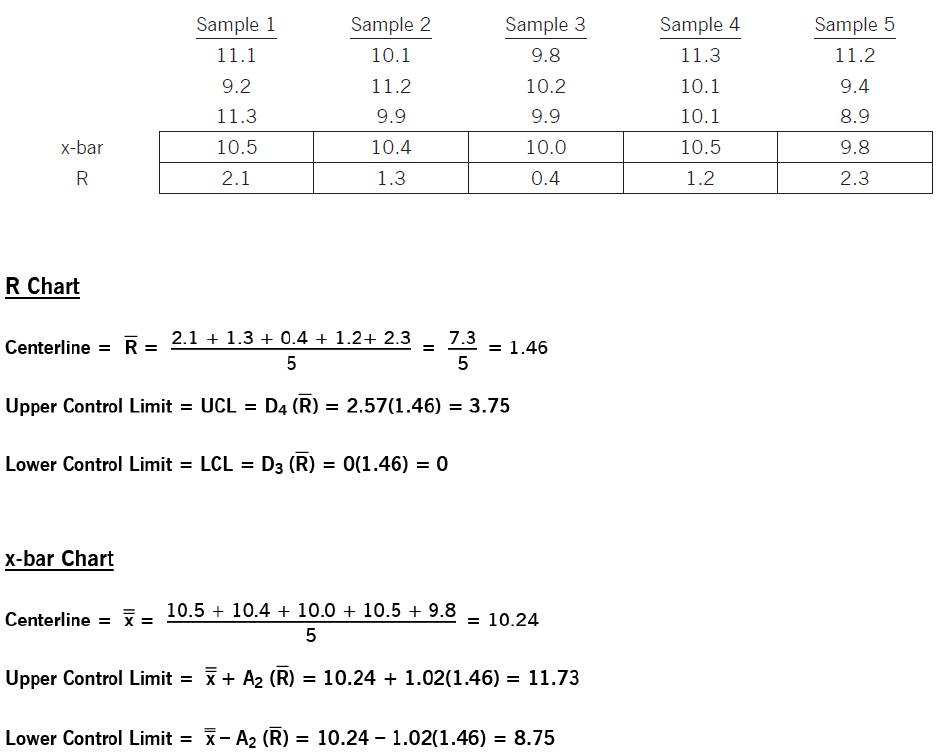

X Bar R Chart Example

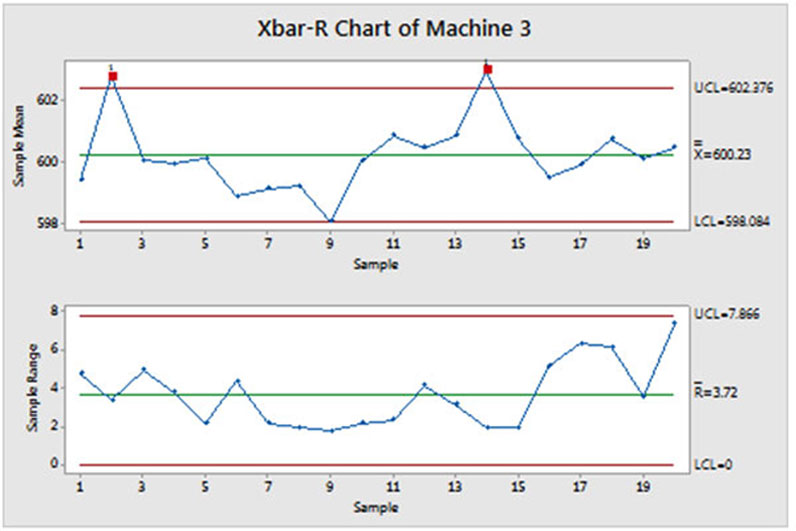

How To Plot Xbar And R Bar Chart In Excel Acetored vrogue.co

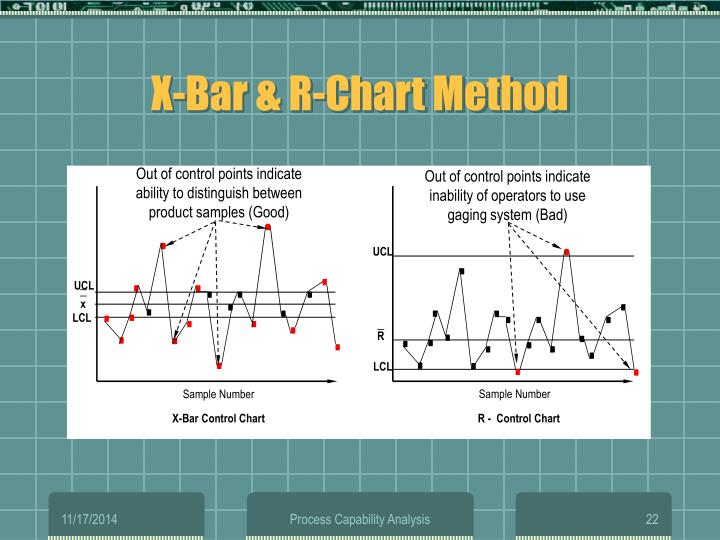

How To Analyze Xbar And R Charts Chart Walls

PPT Chapter 18 Introduction to Quality and Statistical Process

PPT X AND R CHART EXAMPLE INCLASS EXERCISE PowerPoint Presentation

PPT X AND R CHART EXAMPLE INCLASS EXERCISE PowerPoint Presentation

Xbar and R Chart Formula and Constants The Definitive Guide

X Bar R Charts Are The Widely Used Control Charts For Variable Data To Examine The Process Stability In Many Industries (Like Hospital Patients’ Blood Pressure Over Time, Customer Call Handle Times, Length Of A.

It Plots The Mean (X Bar) And Range (R) Of Each Subgroup Of Samples.

Related Post: