Sika 1A Color Chart

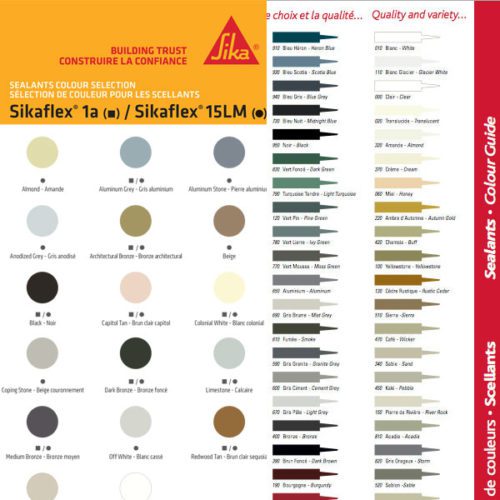

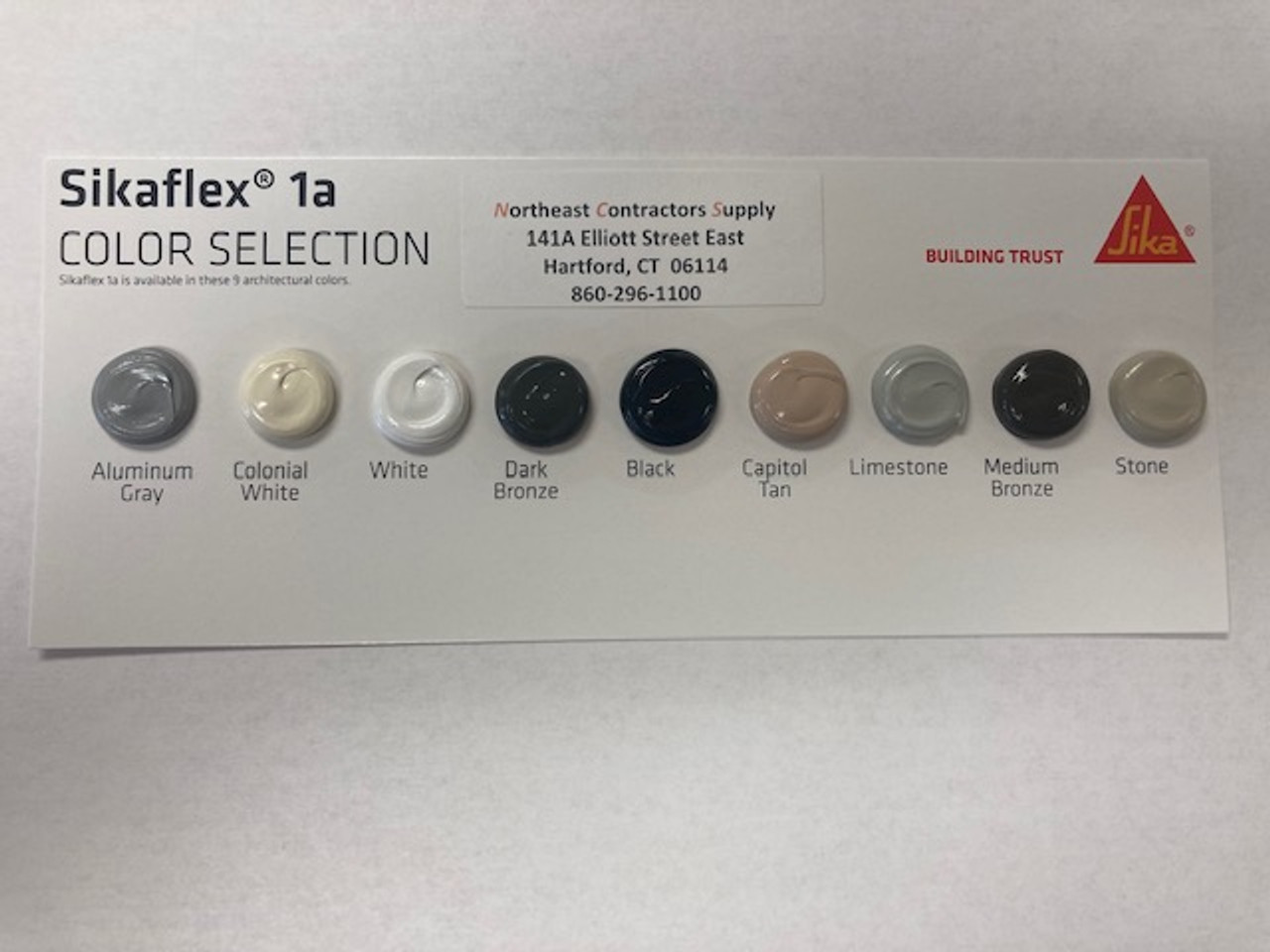

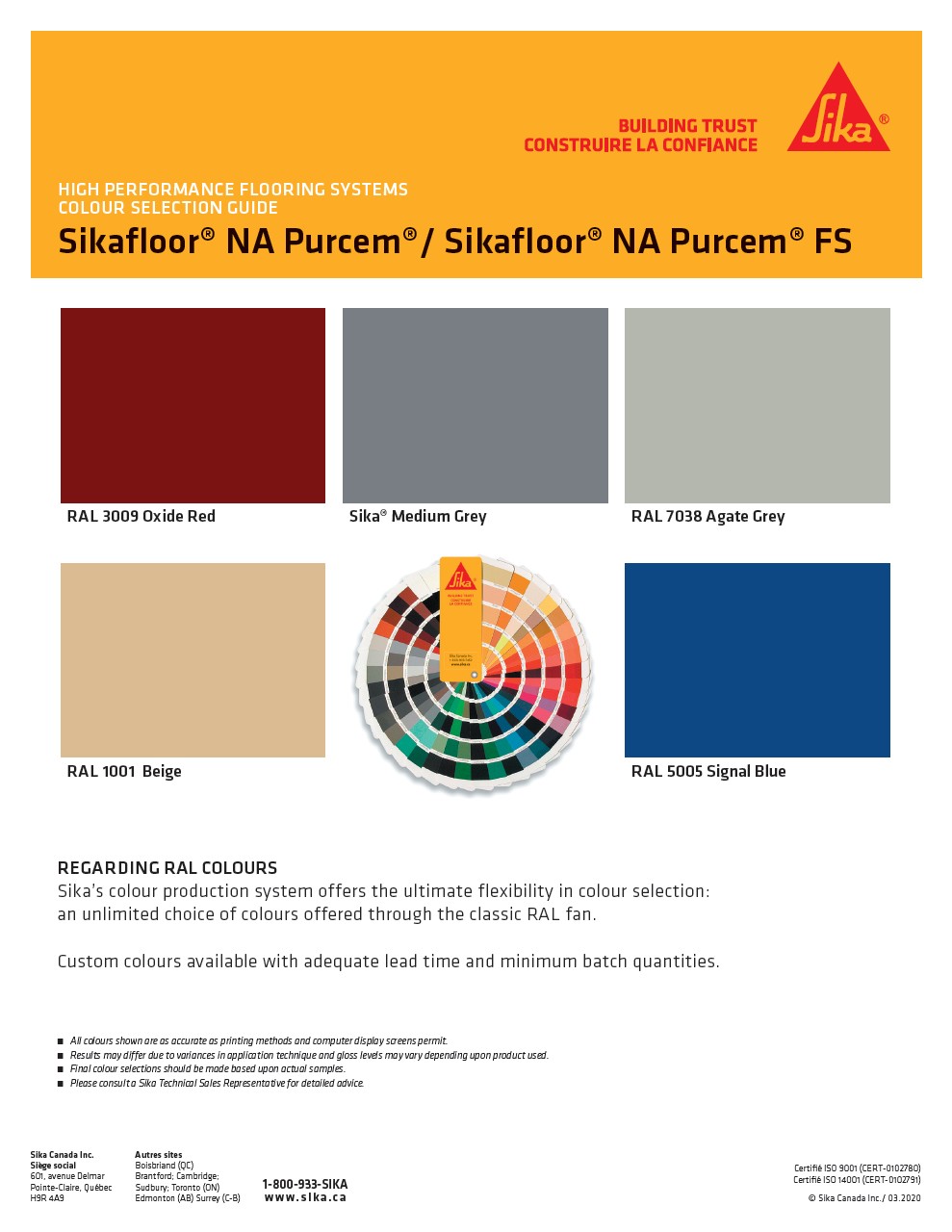

Sika 1A Color Chart - Sikalastic roofpro top coat color chart. Apply between 40°f and 100°f. For personal protection see section 8. A self leveling sealant with an accelerated curing capacity for sealing horizontal expansion joints in concrete. Able to bridge gaps up to 1.5 in. • wait approximately 7 days before painting, sanding or immersing sikaflex or sikabond in water. Polyurethane sealant, sikaflex 1a, elastomeric joint sealant, elastomeric sealant, architectural sealants, joint sealant, polyurethane caulk, elastomeric roof coating, sikaflex 1a sealant, elastomeric caulk created date: Web sika warrants this product for one year from date of installation to be free from manufacturing defects and mecl the technical properties on the current technical data sheet if used as directed within shell lire. Color of actual product may vary slightly from this color guide. As with other coloured material, there may be variations in colour across differing batches. Web sika color charts are designed to help professionals select their sealant color from a range of options that are available. * exact color only achievable with sikasil fps. Polyurethane sealant, sikaflex 1a, elastomeric joint sealant, elastomeric sealant, architectural sealants, joint sealant, polyurethane caulk, elastomeric roof coating, sikaflex 1a sealant, elastomeric caulk created date: Sika is the manufacturer of sikaflex, a highly versatile sealing compound and adhesive. Sikalastic traffic systems standard top coat color chart. Sikalastic roofpro top coat color chart. Apply between 40°f and 100°f. Sikagard flexcoat atc color chart. Aluminum gray, black, capital tan, colonial white, dark bronze, limestone, medium bronze, stone, white, and custom colors are available upon request. Special architectural colors on request. The product meets the required standards for both outdoor and indoor use. As with other coloured material, there may be variations in colour across differing batches. Web • for best results store sikaflex and sikabond at approximately 70°f for about 24 hours prior to use. Sikalastic roofpro top coat color chart. Web sika sikaflex 1a is available in many standard. A self leveling sealant with an accelerated curing capacity for sealing horizontal expansion joints in concrete. N light colors can yellow if exposed to direct gas fired heating element. Sika warrants this product for one year from date of installation to be free from manufacturing defects and to meet the technical properties on the current technical data sheet if used. All colours shown are as accurate as printing methods and computer display screens permit. Sika is the manufacturer of sikaflex, a highly versatile sealing compound and adhesive. Sika warrants this product for one year from date of installation to be free from manufacturing defects and to meet the technical properties on the current technical data sheet if used as directed. For personal protection see section 8. Sikalastic traffic systems standard top coat color chart. • wait approximately 3 days before exposing sikaflex or sikabond to foot traffic. As with other coloured material, there may be variations in colour across differing batches. N the depth of sealant in horizontal joints subject to traffic is. Sika warrants this product for one year from date of installation to be free from manufacturing defects and to meet the technical properties on the current technical data sheet if used as directed within shelf life. Able to bridge gaps up to 1.5 in. No tooling required, levels itself. N light colors can yellow if exposed to direct gas fired. Web n white color tends to yellow slightly when exposed to ultraviolet rays. Sika warrants this product for one year from date of installation to be free from manufacturing defects and to meet the technical properties on the current technical data sheet if used as directed within shelf life. Capable of ± 35 % joint movement. Sika is the manufacturer. As with other coloured material, there may be variations in colour across differing batches. Capable of ± 35 % joint movement. N light colors can yellow if exposed to direct gas fired heating element. A self leveling sealant with an accelerated curing capacity for sealing horizontal expansion joints in concrete. Web do not get in eyes, on skin, or on. Web do not get in eyes, on skin, or on clothing. Sikalastic traffic systems standard top coat color chart. Apply between 40°f and 100°f. N light colors can yellow if exposed to direct gas fired heating element. Highly elastic, this sealant cures to a tough and flexible consistency with excellent cut and tear resistance. Sikagard flexcoat atc color chart. Web • for best results store sikaflex and sikabond at approximately 70°f for about 24 hours prior to use. Capable of ± 35 % joint movement. All colours shown are as accurate as printing methods and computer display screens permit. N the depth of sealant in horizontal joints subject to traffic is. Sikagard flexcoat atc color chart. No tooling required, levels itself. Web sika warrants this product for one year from date of installation to be free from manufacturing defects and mecl the technical properties on the current technical data sheet if used as directed within shell lire. For best results, the final color approval must be done after sealant is mixed. Sika is the manufacturer of sikaflex, a highly versatile sealing compound and adhesive. Color of actual product may vary slightly from this color guide. • wait approximately 7 days before painting, sanding or immersing sikaflex or sikabond in water. It is advisable to allocate batches to particular sections of the application. Eliminates time, effort, and equipment for mixing, filling cartridges and. * exact color only achievable with sikasil fps. Polyurethane sealant, sikaflex 1a, elastomeric joint sealant, elastomeric sealant, architectural sealants, joint sealant, polyurethane caulk, elastomeric roof coating, sikaflex 1a sealant, elastomeric caulk created date: Web our foundation careers manufacturer surcharges. Sikalastic traffic systems standard top coat color chart. Sika warrants this product for one year from date of installation to be free from manufacturing defects and to meet the technical properties on the current technical data sheet if used as directed within shelf life. Web • for best results store sikaflex and sikabond at approximately 70°f for about 24 hours prior to use. Web sika warrants this product for one year from date of installation to be free from manufacturing defects and mecl the technical properties on the current technical data sheet if used as directed within shell lire. Apply between 40°f and 100°f. Web do not get in eyes, on skin, or on clothing. • wait approximately 3 days before exposing sikaflex or sikabond to foot traffic. Sika warrants this product for one year from date of installation to be free from manufacturing defects and to meet the technical properties on the current technical data sheet if used as directed within shelf life.Charte des couleurs calfeutrages Arcan Aluminium

Sika 1A Color Chart

Sika 1a Color Chart

Sikaflex 1a Color Chart

Sikasil Color Chart

Color Selection · Sealants · Sika Emseal

Sika Color Chart

Sikaflex 1a Color Chart

Sika 1a Color Chart

Sika Flooring Color Chart My Bios

Web Sika Color Charts Are Designed To Help Professionals Select Their Sealant Color From A Range Of Options That Are Available.

Construction Sealant Is Single Component Polyurethane Used To Seal Joints And Gaps In Walls, Floors, Balconies, Around Window And Door Frames And Other Building Gaps.

It Is Paintable, Stainable And Sandable And.

N Light Colors Can Yellow If Exposed To Direct Gas Fired Heating Element.

Related Post: