Press Brake Tonnage Chart

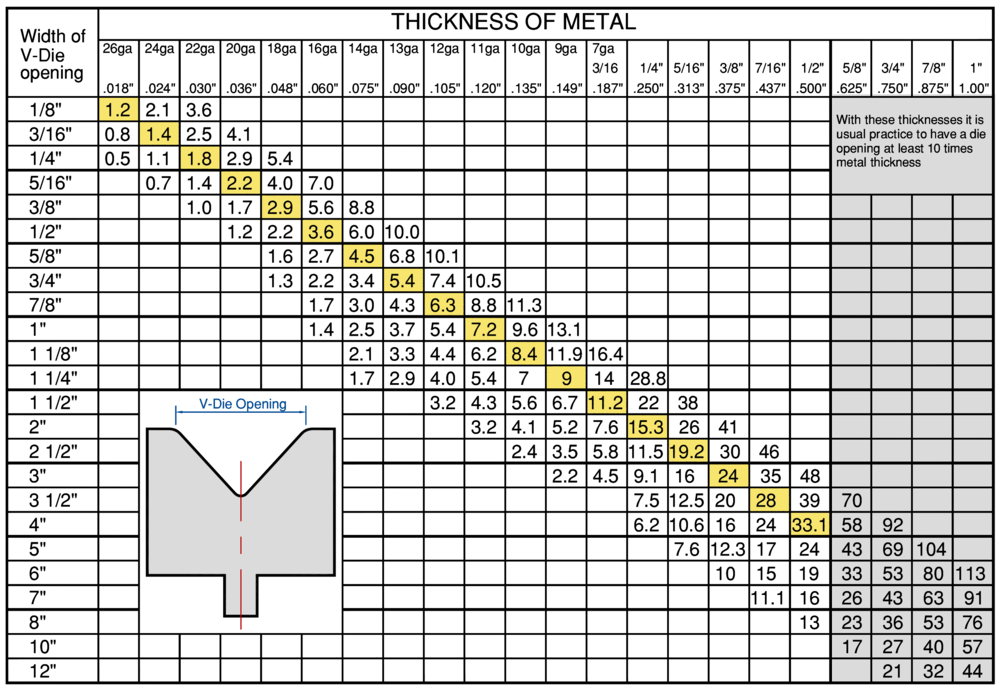

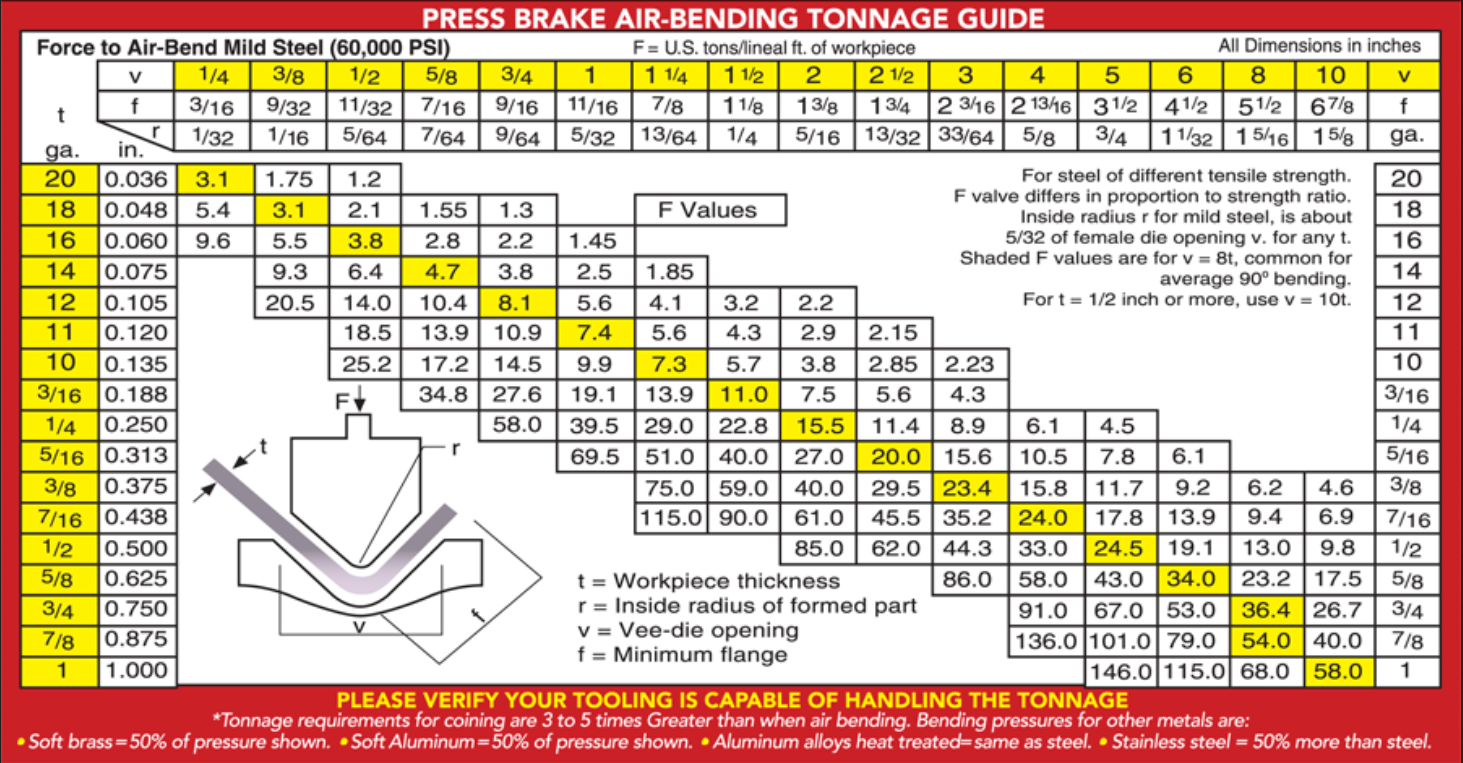

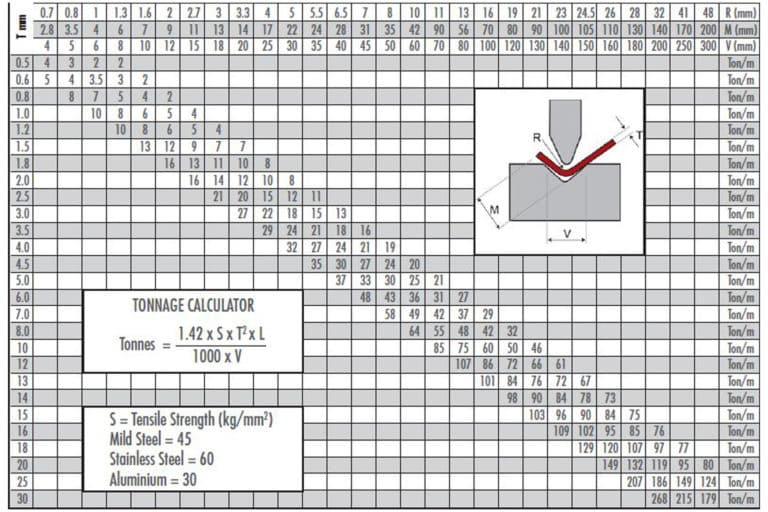

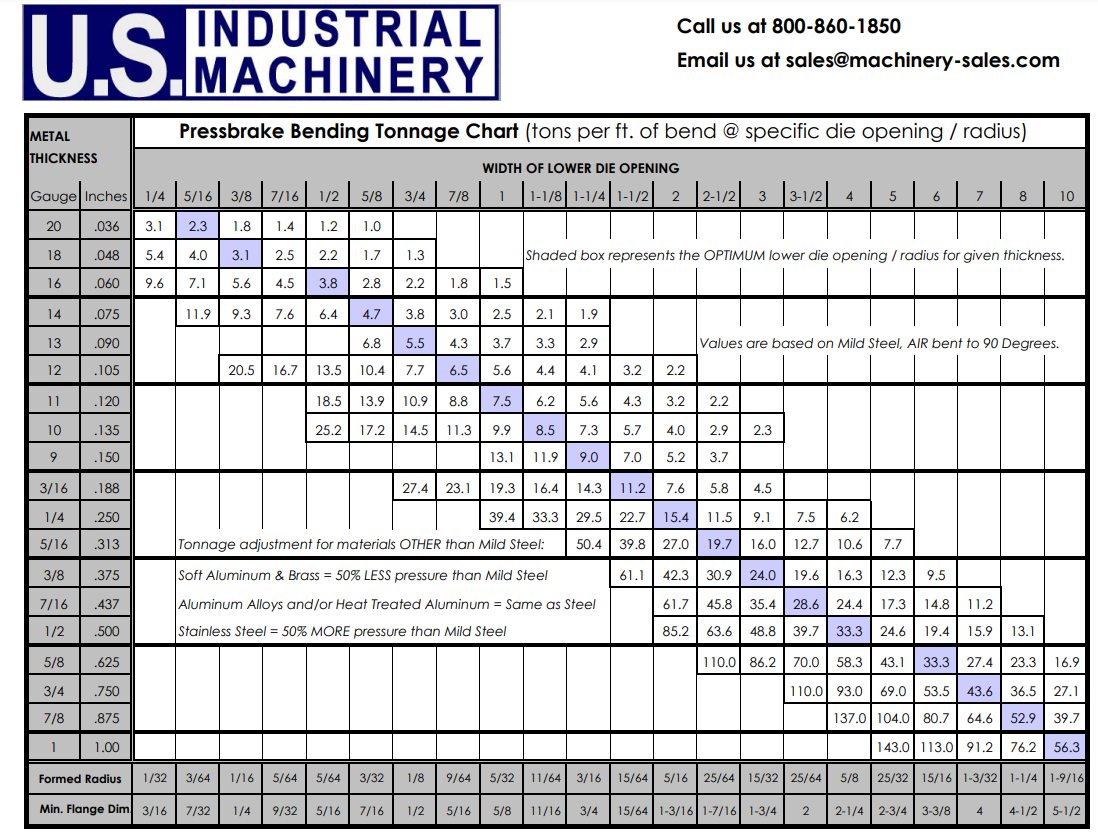

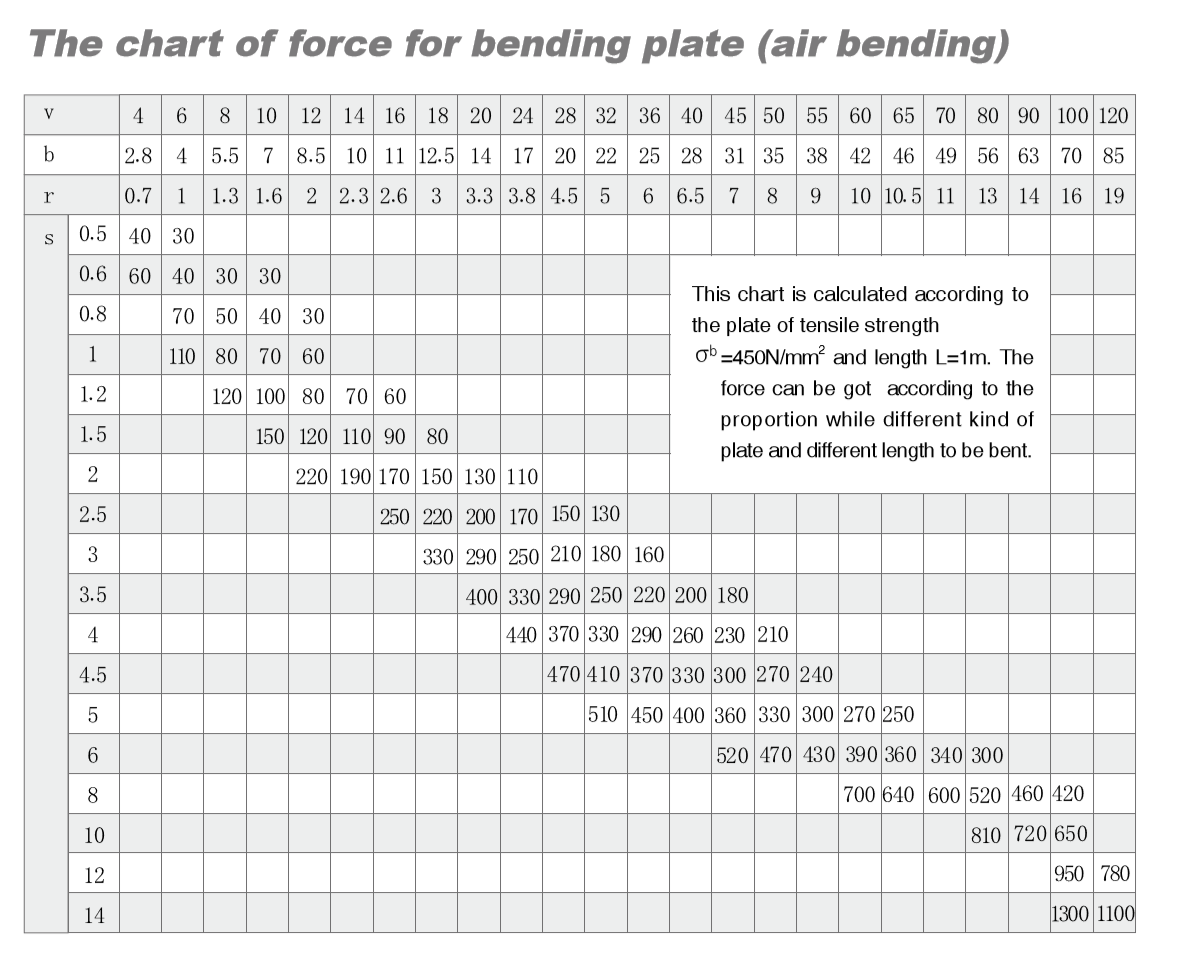

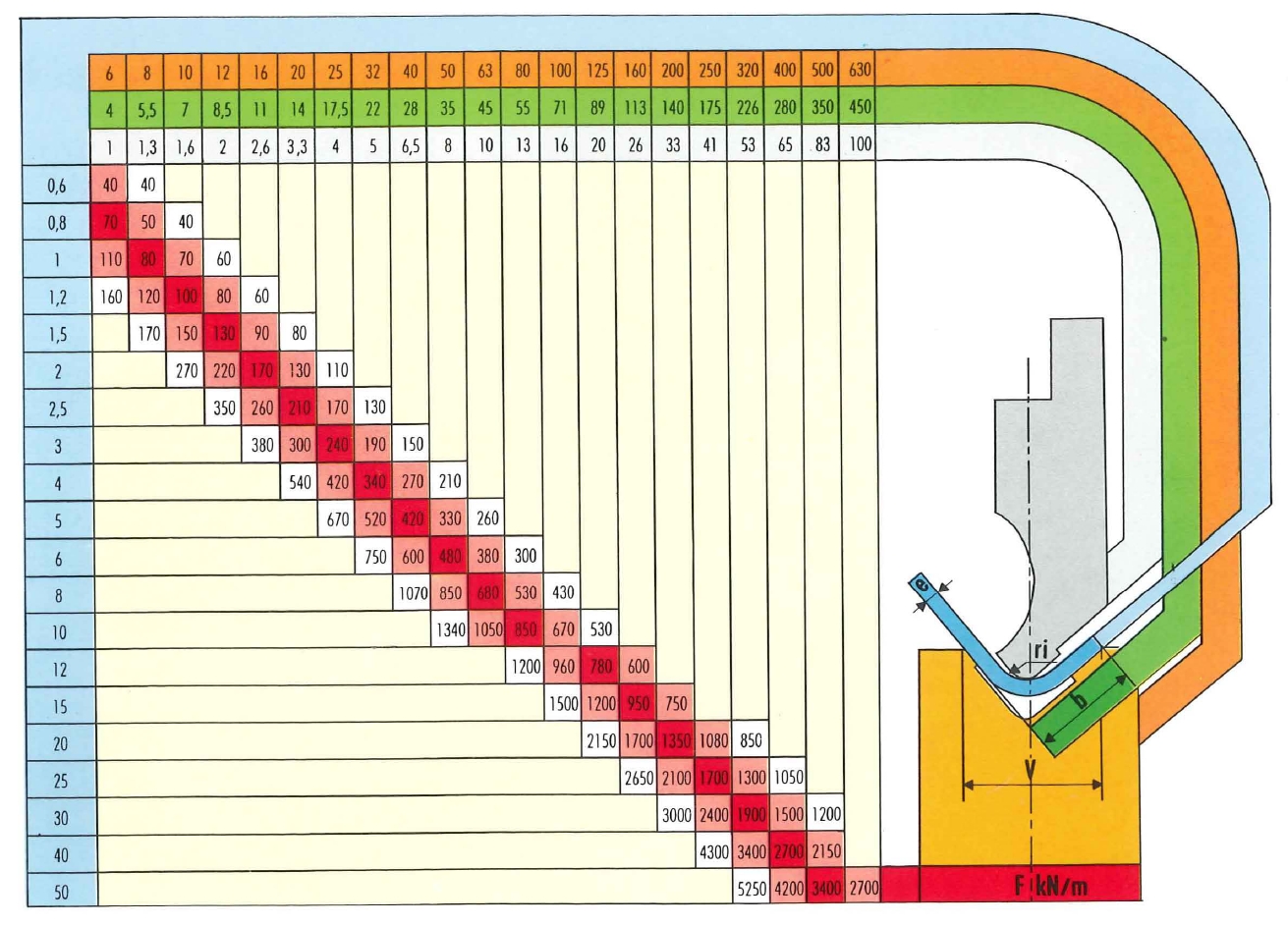

Press Brake Tonnage Chart - Punch with radius equal to metal thickness and die opening approximately 8 times the metal thickness. Bending pressures required for other metals compared. Of bend @ specific die opening / radius) thickness. Web disclaimer | instructions site solution by new creation consulting These values are dependent upon the radius of the dies, the yield strength of the material, the temper of the material, the direction of. Web uk based providers of press brake tooling and cnc press brake. Get accurate results quickly and easily. Web press brake metric calculator of bending force and tonnage online with tonnage force chart and formulas to use. Discover how to use these calculations to avoid common pitfalls, ensuring both the longevity of your equipment and the quality of your bends. Pressbrake bending tonnage chart (tons per ft. Perfect for engineers and fabricators. Required to make a 90 degree air bend in mild steel. Web disclaimer | instructions site solution by new creation consulting Web the tonnages indicated in black boxes are the die openings 8 times metal thickness below 1/4, the tonnages indicated in red boxes are for die opening 10 times metal thickness of 1/4 and above. Punch with radius equal to metal thickness and die opening approximately 8 times the metal thickness. It is expressed in tons and represents the maximum amount of pressure that the. Web use this quick bending calculator tool to input material type and thickness, die and punch parameters, and overall bending length. Web calculate the tonnage of your press brake with our online calculator. Products include smooth planed, high tech, euro spec tools, guillotine blades, bending charts. Shaded figures represent ideal conditions for light angle bending; Punch with radius equal to metal thickness and die opening approximately 8 times the metal thickness. Web press brake tonnage calculator is a measure of the amount of force a press brake can exert on a piece of metal during the bending process. This calculator is designed to estimate approximate press brake tonnage requirements for air bending. Web calculate the. Discover how to use these calculations to avoid common pitfalls, ensuring both the longevity of your equipment and the quality of your bends. Web disclaimer | instructions site solution by new creation consulting Of bend @ specific die opening / radius) thickness. This calculator is designed to estimate approximate press brake tonnage requirements for air bending. Punch with radius equal. Approximate pressure in tons per linear foot required to make 90 degree air bend in mild steel. Web the following press brake tonnage chart is used by many press brake manufacturers both in china and abroad countries. Web constants (press brake tonnage): Punch with radius equal to metal thickness and die opening approximately 8 times the metal thickness. (check out. This calculator is designed to estimate approximate press brake tonnage requirements for air bending. (check out the quick reference press brake tonnage chart). Products include smooth planed, high tech, euro spec tools, guillotine blades, bending charts. Web constants (press brake tonnage): It is only an estimate and not intended to be used as a recommendation. Pressbrake bending tonnage chart (tons per ft. Web disclaimer | instructions site solution by new creation consulting Web a press brake tonnage chart is a valuable tool that helps determine the required tonnage for bending different materials and thicknesses. It is only an estimate and not intended to be used as a recommendation. Discover how to use these calculations to. Products include smooth planed, high tech, euro spec tools, guillotine blades, bending charts. Web uk based providers of press brake tooling and cnc press brake. Web press brake tonnage calculator is a measure of the amount of force a press brake can exert on a piece of metal during the bending process. Perfect for fabricators and engineers, our accurate tool. Web vee die opening in. Tensile mild steel on chart: Web uk based providers of press brake tooling and cnc press brake. Web disclaimer | instructions site solution by new creation consulting These values are dependent upon the radius of the dies, the yield strength of the material, the temper of the material, the direction of. (check out the quick reference press brake tonnage chart). Web constants (press brake tonnage): Shaded figures represent ideal conditions for light angle bending; Pressbrake bending tonnage chart (tons per ft. Web disclaimer | instructions site solution by new creation consulting Perfect for fabricators and engineers, our accurate tool ensures precise bending force calculations for optimal metal forming results. Web the following press brake tonnage chart is used by many press brake manufacturers both in china and abroad countries. Web press brake tonnage calculator is a measure of the amount of force a press brake can exert on a piece of. Punch with radius equal to metal thickness and die opening approximately 8 times the metal thickness. Web the following press brake tonnage chart is used by many press brake manufacturers both in china and abroad countries. Get accurate results quickly and easily. (check out the quick reference press brake tonnage chart). Approximate pressure in tons per linear foot required to. (check out the quick reference press brake tonnage chart). It takes into account factors such as the material type, thickness, and. Products include smooth planed, high tech, euro spec tools, guillotine blades, bending charts. Perfect for fabricators and engineers, our accurate tool ensures precise bending force calculations for optimal metal forming results. The inside radius of a right angle bend is approximately equal to the thickness of the material. Web press brake tonnage calculator is a measure of the amount of force a press brake can exert on a piece of metal during the bending process. The charts to the right give the approximate pressure. Web the cincinnati press brake load calculator will calculate the tonnage to form a part with the variables of material type, vee die opening, bend length, and material thickness inputted. These values are dependent upon the radius of the dies, the yield strength of the material, the temper of the material, the direction of. Get accurate results quickly and easily. Web calculate the tonnage of your press brake with our online calculator. Web the tonnages indicated in black boxes are the die openings 8 times metal thickness below 1/4, the tonnages indicated in red boxes are for die opening 10 times metal thickness of 1/4 and above. Punch with radius equal to metal thickness and die opening approximately 8 times the metal thickness. Required to make a 90 degree air bend in mild steel. Shaded figures represent ideal conditions for light angle bending; Web this article dives into the essentials of calculating press brake tonnage, explaining the critical factors like material type, sheet thickness, and bend length.How to Calculate Press Brake Tonnage BLMA machinery

FAQ — Power Brake Dies

Titan 25T CNC Press brake

Press Brake Tonnage Chart

Useful Charts Resources Hweiss Machinery & Supply

Press Brake Toolings, A Guide to Punches and Dies Selmach™

What is a press brake and why do I need one?

Press Brake Machines, Memphis, TN U.S. Industrial Machinery

Press Brake Tonnage Calculation Metalforming Tonnage Chart

Hydraulic PressBrake

Perfect For Engineers And Fabricators.

This Calculator Is Designed To Estimate Approximate Press Brake Tonnage Requirements For Air Bending.

Web Disclaimer | Instructions Site Solution By New Creation Consulting

By Utilizing This Chart, Fabricators Can Ensure Accurate And Precise Bends,.

Related Post: