Copper Fitting Take Off Chart

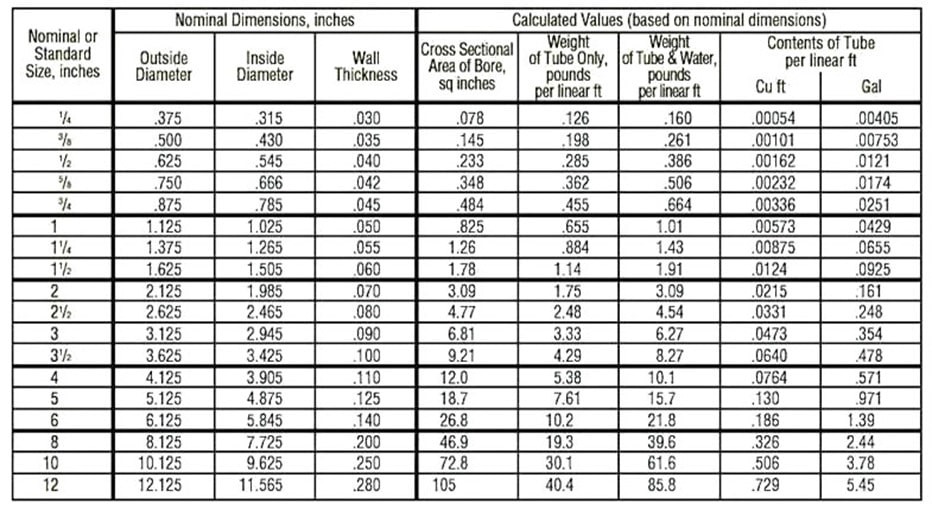

Copper Fitting Take Off Chart - Web a h e a d o f ®t h e f l o w www.nibco.com nibco inc. As suggested by bcworkz, tables for a given diameter and style of pipe are the best method for an accurate measurement. Please refer to nibco technical data sheets and catalogs for engineering and installation information. Check & lubricate gasket check gasket to be sure it is compatible for the intended service. Significant time savings means tight budgets and deadlines are met while project delays and cost overruns are avoided. Web because of the accuracy of construc ion and design, copper plumbing is more efficient and less expensive. Index of tables and figures that represent the supporting technical data. For threaded fittings, double the allowances shown in the table. It is used when velocity is not a problem. Web streamline® wrot copper pressure and dwv fittings for use in plumbing or mechanical applications. Web quick and easy the nibco® press system® is user friendly, quick and easy to install. Web to get the take off of a fitting, it is measured from where the copper tube bottoms out in the fitting, to the center line of the fitting. To simplify, write your specifications to read: Clean outside of tube to remove oxides using an emery cloth. Web a copper fitting take off chart is a handy resource that provides accurate measurements for various types of copper fittings based on pipe size and application. Figure 14.7 brazing flux recommendations. It helps plumbers and contractors determine the correct dimensions needed for. Significant time savings means tight budgets and deadlines are met while project delays and cost overruns are avoided. World headquarters • 1516 middlebury st. Ream the cut end to remove the inside and outside burr of tube. Installation can be completed in less time than traditional solder, threaded, brazed or grooved copper systems. Pressure loss in fittings and valves expressed as equivalent length of tube, feet. Web because of the accuracy of construc ion and design, copper plumbing is more efficient and less expensive. Lead free refers to the wetted surface of pipe, fittings and fixtures in. Web a h e a d o f ®t h e f l o w www.nibco.com nibco inc. Clean outside of tube to remove oxides using an emery cloth. By using this site, you agree to the use of these cookies. Installation can be completed in less time than traditional solder, threaded, brazed or grooved copper systems. Index of tables. Web a copper fitting take off chart is a handy resource that provides accurate measurements for various types of copper fittings based on pipe size and application. To simplify, write your specifications to read: By using this site, you agree to the use of these cookies. To simplify, write your specifications to read: Allowances are for streamlined soldered fittings and. World headquarters • 1516 middlebury st. For threaded fittings, double the allowances shown in the table. Index of tables and figures that represent the supporting technical data. To simplify, write your specifications to read: Allowances are for streamlined soldered fittings and recessed threaded fittings. Significant time savings means tight budgets and deadlines are met while project delays and cost overruns are avoided. Web nibco uses cookies to help us improve your overall experience. Check & lubricate gasket check gasket to be sure it is compatible for the intended service. Pressure loss in fittings and valves expressed as equivalent length of tube, feet. As suggested. Check & lubricate gasket check gasket to be sure it is compatible for the intended service. It helps plumbers and contractors determine the correct dimensions needed for. Lead free refers to the wetted surface of pipe, fittings and fixtures in potable water systems that have a weighted average lead It is used when velocity is not a problem. Web to. Web a copper fitting take off chart is a handy resource that provides accurate measurements for various types of copper fittings based on pipe size and application. It helps plumbers and contractors determine the correct dimensions needed for. Significant time savings means tight budgets and deadlines are met while project delays and cost overruns are avoided. Check & lubricate gasket. Web to get the take off of a fitting, it is measured from where the copper tube bottoms out in the fitting, to the center line of the fitting. Allowances are for streamlined soldered fittings and recessed threaded fittings. Web because of the accuracy of construc ion and design, copper plumbing is more efficient and less expensive. Figure 14.7 brazing. Web to get the take off of a fitting, it is measured from where the copper tube bottoms out in the fitting, to the center line of the fitting. Web nibco uses cookies to help us improve your overall experience. Web soldering and brazing copper tube and fittings. Barbed insert fittings for polybutylene. Web because of the accuracy of construc. To simplify, write your specifications to read: World headquarters • 1516 middlebury st. Product is designed to join astm b88 and astm b280 seamless copper tube. Web figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. Web a h e a d o f ®t h e f l o w www.nibco.com. Barbed insert fittings for polybutylene. World headquarters • 1516 middlebury st. Web 6 anvil® pipe fitters handbook gruvlok® installation and assembly figures 7400 & 7401 couplings 1. Although soldering and brazing operations are inherently simple, the deletion or misapplication of a single part of the process may mean the difference between a good joint and a failure. Dimensions of solder joint ends for wrought and cast pressure fittings, inches. Clean outside of tube to remove oxides using an emery cloth. Please refer to nibco technical data sheets and catalogs for engineering and installation information. It helps plumbers and contractors determine the correct dimensions needed for. Ream the cut end to remove the inside and outside burr of tube. Allowances are for streamlined soldered fittings and recessed threaded fittings. “copper tube fittings to be in accordance with specifications as outlined in nibco copper fittings catalog.” wrot copper medical gas. Web streamline® wrot copper pressure and dwv fittings for use in plumbing or mechanical applications. Web figure 14.6 melting temperature ranges for copper and copper alloys, brazing filler metals, brazing flux and solders. Web quick and easy the nibco® press system® is user friendly, quick and easy to install. Web nibco uses cookies to help us improve your overall experience. By using this site, you agree to the use of these cookies.Takeoff Chart Take Off For Threaded Pipe Fittings

Copper Fitting Take Off Chart

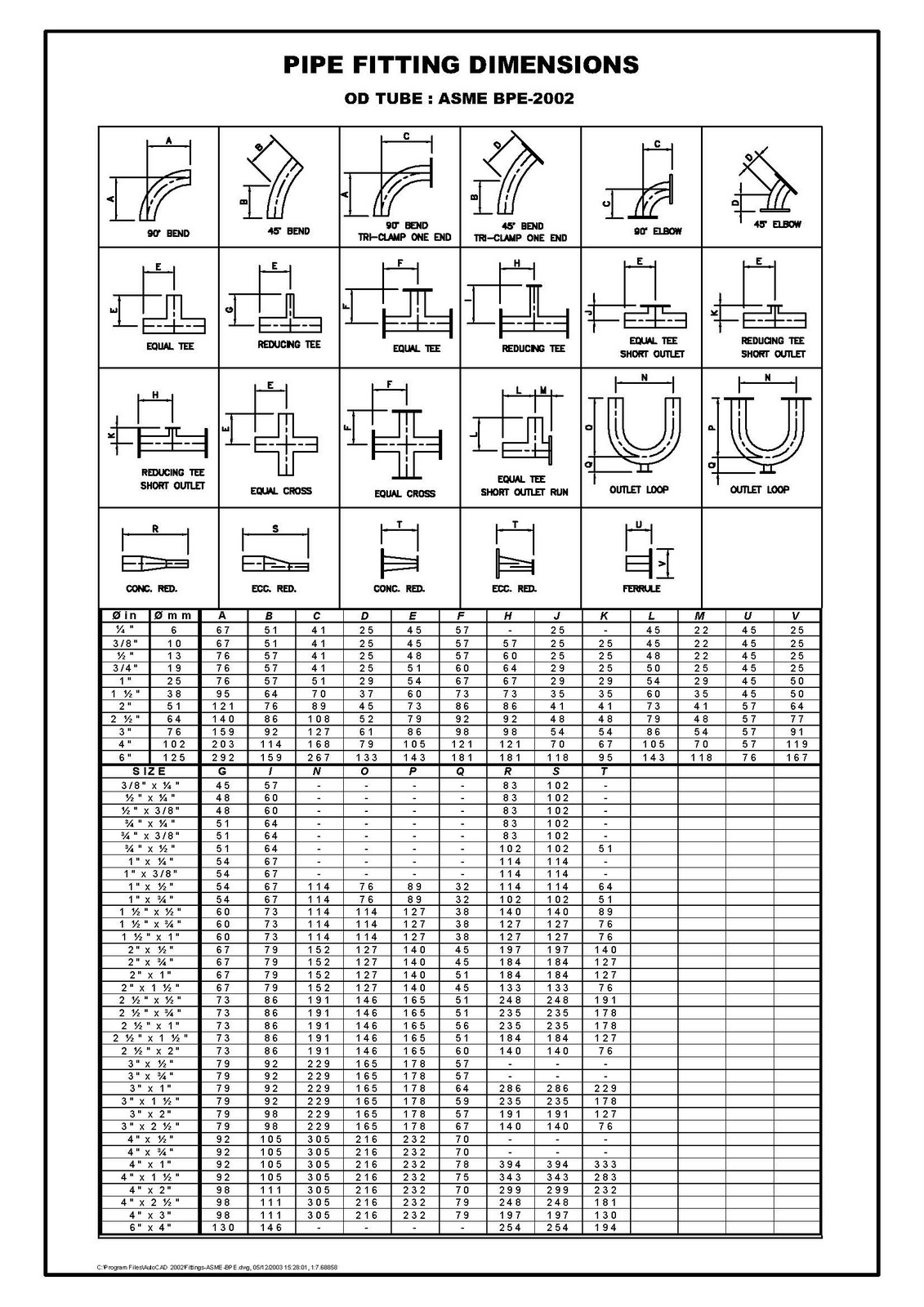

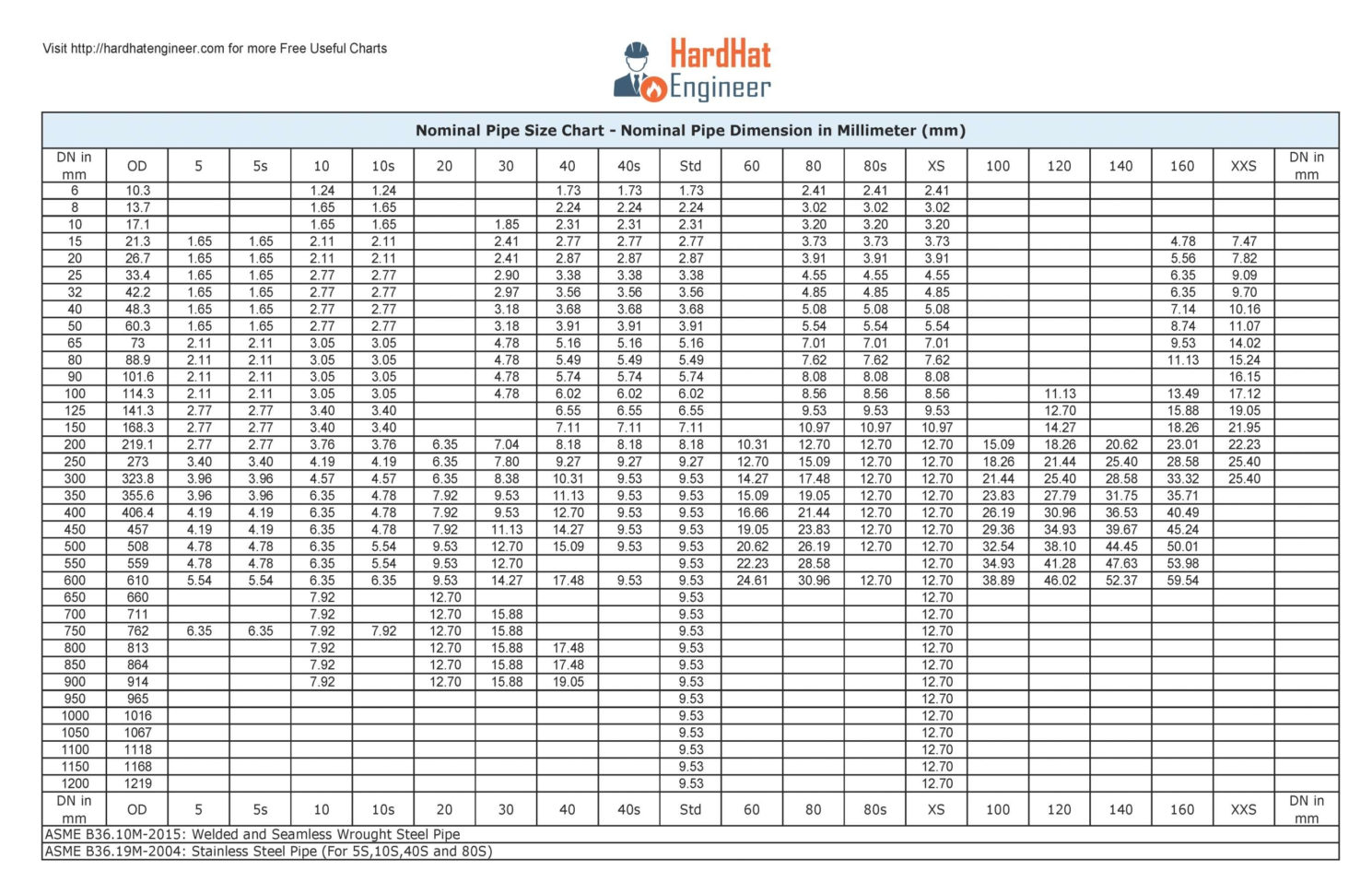

Weld Fitting Take Off Chart

Copper Fittings Chart

Takeoff Chart Take Off For Threaded Pipe Fittings

Copper Fitting Takeoff Chart

Pipe Fitting Take Off Chart

Copper Fitting Technical Info Manibhadra Fittings

Piping Takeoff Spreadsheet Spreadsheet Softwar

Copper Fitting Takeoff Chart

Web To Get The Take Off Of A Fitting, It Is Measured From Where The Copper Tube Bottoms Out In The Fitting, To The Center Line Of The Fitting.

Web Consult Nibco's Entire Copper Fitting Catalog Catalogue On Directindustry.

Significant Time Savings Means Tight Budgets And Deadlines Are Met While Project Delays And Cost Overruns Are Avoided.

Lead Free Refers To The Wetted Surface Of Pipe, Fittings And Fixtures In Potable Water Systems That Have A Weighted Average Lead

Related Post: