Cfm Flex Duct Chart

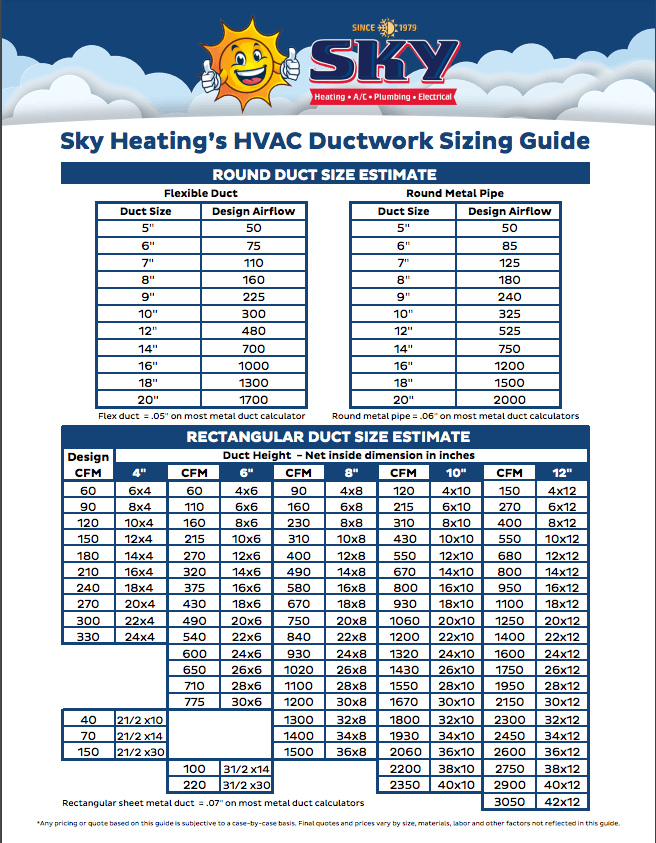

Cfm Flex Duct Chart - To ensure accurate sizing, use the cfm value you calculated earlier and match it to the corresponding duct size on the chart. Multiply the length and width together to get the square footage of the room. You will also find a cfm chart, with airflow in cfm calculated for areas between 100 sq ft and 3,000 sq ft (useful for ductwork as well) further on. The following duct sizes are based on a fraction drop of.10 inches per 100 feet of lineal duct. Round metal ducts and round flexible ducts are the two most common types of ducts used in american houses. Web users can size flex, ductboard, metal, or fabric ducts based on velocity, friction loss, or duct dimensions. The result will be displayed, providing guidance for selecting the appropriate flex duct size for your hvac system. Friction rate velocity friction rate: Use it in one of two ways; Web duct cfm charts. To ensure accurate sizing, use the cfm value you calculated earlier and match it to the corresponding duct size on the chart. Use it in one of two ways; As systems increase in efficiency, the tolerances of “how we have always done it” will no longer be adequate. How many cfm do i need? * include fittings in the duct tel enter either: Web the flexible duct calculator provides a method to calculate friction loss based on duct diameter, airflow, length, and number of bends, enabling users to optimize their duct design for minimal pressure drop and maximum efficiency. Either enter the duct size to find the equivalent cfm, or input the cfm to find the right size of rectangular, round or flex duct. Web below the calculator, we will demonstrate how the cubic feet per minute calculator works by solving one example using the calculator and cfm formula. Multiply the length and width together to get the square footage of the room. Please select a design flow rate to display your results. Web users can size flex, ductboard, metal, or fabric ducts based on velocity, friction loss, or duct dimensions. Web below the calculator, we will demonstrate how the cubic feet per minute calculator works by solving one example using the calculator and cfm formula. Click the “calculate” button to obtain the recommended flex duct size in square inches. Web to figure. Web cfm 4 cfm 6 cfm 8 cfm 10 cfm 12 60 6x4 60 4x6 90 4x8 120 4x10 150 4x12. Flex duct =.05 on most metal duct calculator round metal pipe =.06 on most metal duct calculators. Web duct cfm charts. The hvac experts of jenergy air are very experienced with air duct repairs and installations and have seen. Friction rate velocity friction rate: The following provides the appropriate duct sizes based on different airflow rates and applications. Web for instance a 2.5 ton system (approximately 400 cfm per ton) would require (2) 14” flexible return ducts or (1) very short flexible 18” duct to move the 1000 cfm required by the 2.5 ton system. Web residential duct sizing. Click the “calculate” button to obtain the recommended flex duct size in square inches. As systems increase in efficiency, the tolerances of “how we have always done it” will no longer be adequate. Multiply the length and width together to get the square footage of the room. Web users can size flex, ductboard, metal, or fabric ducts based on velocity,. Figure out the amount of cfm that is required for the room. New duct sizing chart.xls author: Convert rectangular duct to round equivalent. Web residential duct sizing guide. Multiply the length and width together to get the square footage of the room. Web the digitized ductulator is a free online calculator for sizing hvac ducts. Web refer to the duct cfm chart in the hvac manufacturer’s specs to determine the external static pressure of the blower for that specific hvac model. It’s typically displayed as a cfm chart for hvac that breaks down different blower settings and total cfms required for the. Web duct cfm charts. Duct size chart coburns.xls author: Web for instance a 2.5 ton system (approximately 400 cfm per ton) would require (2) 14” flexible return ducts or (1) very short flexible 18” duct to move the 1000 cfm required by the 2.5 ton system. Web using this duct sizing chart, we will teach you just how easy it. It’s typically displayed as a cfm chart for hvac that breaks down different blower settings and total cfms required for the house or building. Web enter the air velocity in feet per minute (fpm). Measure the length and width of the room where the flex duct will be supplying the air. Click the “calculate” button to obtain the recommended flex. Web for instance a 2.5 ton system (approximately 400 cfm per ton) would require (2) 14” flexible return ducts or (1) very short flexible 18” duct to move the 1000 cfm required by the 2.5 ton system. As systems increase in efficiency, the tolerances of “how we have always done it” will no longer be adequate. Web the digitized ductulator. Measure the length and width of the room where the flex duct will be supplying the air. Web the flexible duct calculator provides a method to calculate friction loss based on duct diameter, airflow, length, and number of bends, enabling users to optimize their duct design for minimal pressure drop and maximum efficiency. Web refer to the duct cfm chart. Web these charts guide selecting the appropriate duct size based on the calculated cfm, duct material, and shape. Web for instance a 2.5 ton system (approximately 400 cfm per ton) would require (2) 14” flexible return ducts or (1) very short flexible 18” duct to move the 1000 cfm required by the 2.5 ton system. Use it in one of two ways; Web below the calculator, we will demonstrate how the cubic feet per minute calculator works by solving one example using the calculator and cfm formula. Web users can size flex, ductboard, metal, or fabric ducts based on velocity, friction loss, or duct dimensions. Web using this duct sizing chart, we will teach you just how easy it is to tell if your air ducts are undersized, oversized, or badly installed. Convert rectangular duct to round equivalent. Web duct cfm charts. Either enter the duct size to find the equivalent cfm, or input the cfm to find the right size of rectangular, round or flex duct. New duct sizing chart.xls author: The result will be displayed, providing guidance for selecting the appropriate flex duct size for your hvac system. To ensure accurate sizing, use the cfm value you calculated earlier and match it to the corresponding duct size on the chart. It’s typically displayed as a cfm chart for hvac that breaks down different blower settings and total cfms required for the house or building. Measure the length and width of the room where the flex duct will be supplying the air. Web the flexible duct calculator provides a method to calculate friction loss based on duct diameter, airflow, length, and number of bends, enabling users to optimize their duct design for minimal pressure drop and maximum efficiency. From there, you can determine if your current system is powerful enough to meet the airflow and air changes needs in your home.Flex Duct Sizing Chart Duct Cfm Chart Rectangular Duc vrogue.co

Flex Duct Sizing Chart Cfm Ductwork Sizing Chart Sexiz Pix

Duct Cfm Sizing Chart

Cfm Chart Duct Size

Flex Duct Sizing Chart Templates Printable Free

Cfm To Duct Size Chart

Cfm Chart Flex Duct

Duct Cfm Sizing Chart

Round Ductwork Cfm Chart

Duct CFM Chart Round & Flex Duct Calculation Guide aircondlounge

One Size Is Given For Round Ducts, Its Diameter.

Web We Have Included Charts For Most Of The Popular Standard Air Duct Sizes.

This Tool May Be Used To Comply With The Requirements Of 2015 Irc Section M1506.2 And 2018 Irc Section M1504.2.

Please Select A Design Flow Rate To Display Your Results.

Related Post: